The global semiconductor industry has entered an era of unprecedented geopolitical tension and supply chain restructuring. Against this backdrop, China's ambitious drive to develop domestic semiconductor manufacturing capabilities has taken on new urgency. At the heart of this effort lies the critical challenge of equipment localization - reducing dependence on foreign suppliers for the sophisticated tools needed to produce advanced chips.

The Current Landscape of Semiconductor Equipment Dependence

China's semiconductor industry currently relies heavily on imported equipment, particularly for the most advanced process nodes. Leading international suppliers like ASML, Applied Materials, Lam Research, and Tokyo Electron dominate key segments of the equipment market. This dependence creates strategic vulnerabilities, as evidenced by recent export controls that have restricted China's access to certain advanced semiconductor manufacturing tools.

The localization rate varies significantly across different types of equipment. While some mature node equipment has achieved notable domestic production, the most sophisticated tools - especially extreme ultraviolet (EUV) lithography systems - remain completely dependent on foreign suppliers. This imbalance has spurred both government and industry to accelerate development across the entire equipment spectrum.

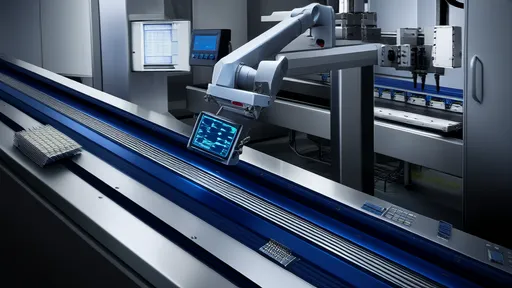

Progress in Key Equipment Categories

In lithography, China's SMEE has made progress with deep ultraviolet (DUV) systems, though still lagging behind ASML's market-leading technology. The Shanghai-based company has reportedly achieved 28nm capability with its SSA/800-10W scanner, representing significant progress but still far from cutting-edge EUV systems needed for 7nm and below.

Etch equipment has seen more substantial breakthroughs, with domestic producers like AMEC and Naura capturing meaningful market share. These companies have developed plasma etch systems capable of supporting advanced nodes, with some tools reportedly qualified for 5nm production lines. The progress in etch demonstrates that targeted investment and talent acquisition can yield competitive products in specific equipment segments.

Thin film deposition represents another area of growing domestic capability. Companies like Piotech and Naura have developed physical vapor deposition (PVD) and atomic layer deposition (ALD) systems that are being adopted by Chinese fabs. While these tools may not yet match the performance and reliability of market leaders, they provide viable alternatives for many production requirements.

The Ecosystem Challenge

Developing individual equipment pieces is only part of the challenge. Semiconductor manufacturing requires tightly integrated ecosystems where different tools work seamlessly together. This creates a chicken-and-egg problem - domestic fabs hesitate to adopt unproven domestic equipment, while equipment makers struggle to improve without production experience.

The Chinese government has attempted to address this through coordinated initiatives that bring together fabs, equipment makers, and materials suppliers. Programs like the "02 Special Project" provide funding and policy support to foster collaboration across the supply chain. These efforts aim to create virtuous cycles where incremental improvements in one area lift capabilities across the ecosystem.

Materials and Components: The Hidden Bottleneck

Even as equipment makers make progress, dependence on foreign-sourced components and materials remains a constraint. Critical subsystems like precision optics, advanced sensors, and specialized pumps often still need to be imported. Similarly, many process chemicals and specialty gases come from overseas suppliers.

Chinese companies are working to develop domestic alternatives, but these efforts face significant technical hurdles. The materials science required for high-purity chemicals or defect-free silicon wafers represents decades of accumulated know-how that cannot be easily replicated. Progress in these foundational areas will largely determine the ultimate ceiling for equipment localization.

Talent and Intellectual Property Considerations

The human capital challenge may be the most difficult to solve quickly. Semiconductor equipment development requires rare combinations of physics, materials science, and precision engineering expertise. China has dramatically expanded its semiconductor education programs and attracted overseas talent, but experience in cutting-edge equipment design remains concentrated in a few global hubs.

Intellectual property presents another complex issue. While legitimate technology transfer and organic R&D have driven much of the progress, allegations of IP theft have created legal and reputational risks for some Chinese equipment companies. Navigating these challenges while accelerating innovation will require careful balancing.

Geopolitical Factors Reshaping the Roadmap

Export controls and technology restrictions have forced China to accelerate its localization timeline while simultaneously making the task more difficult. The inability to access certain foreign tools or components has created immediate pain points but also strengthened the resolve to develop domestic alternatives.

This dynamic has led to some reordering of priorities within China's equipment development roadmap. Areas where foreign alternatives are completely blocked (like EUV lithography) have received increased focus, even as they represent the most challenging technical hurdles. At the same time, segments where partial domestic capability exists are seeing accelerated investment to achieve full self-sufficiency.

The Role of National Champions

China's strategy has emphasized the development of national champions in semiconductor equipment - companies like Naura, AMEC, and SMEE that receive substantial state support. These firms benefit from preferential procurement policies, R&D subsidies, and access to government-backed investment.

While this approach has shown results in certain equipment categories, questions remain about its effectiveness across the entire spectrum of needed technologies. The semiconductor equipment market has historically favored highly specialized companies rather than broad-based conglomerates, suggesting China may need to cultivate a more diverse ecosystem of equipment specialists.

Alternative Paths and Architectural Innovation

Facing challenges in directly replicating existing equipment architectures, some Chinese researchers and companies are exploring alternative approaches. This includes work on novel patterning techniques that might reduce lithography dependence, or new transistor architectures that could be manufactured with less sophisticated equipment.

While most industry experts view such disruptive innovations as long shots, they represent potential wild cards in the localization equation. Even partial success in developing alternative manufacturing approaches could change the calculus of equipment requirements.

The Mature Node Opportunity

Much attention focuses on advanced logic nodes, but equipment for mature nodes (28nm and above) represents a more immediately addressable market. Many automotive, industrial, and IoT applications continue to use these established technologies, creating substantial demand.

Chinese equipment makers have made particular progress in this segment, with localization rates reportedly exceeding 50% for some mature node tools. This provides a foundation for revenue generation and continuous improvement while working on more advanced capabilities.

Looking Ahead: Realistic Timelines and Milestones

Industry observers estimate China may achieve 70-80% self-sufficiency for mature node equipment within 3-5 years, with certain critical gaps remaining. For advanced nodes below 14nm, the timeline stretches much longer - potentially a decade or more for comprehensive capability.

The ultimate success of China's equipment localization drive will depend on sustained investment, talent development, and the ability to foster genuine innovation rather than just imitation. While political will and financial resources are substantial, the technical challenges represent some of the most difficult engineering problems in modern manufacturing.

As the global semiconductor industry continues to evolve amid geopolitical tensions, China's equipment localization efforts will remain a critical factor shaping the future balance of technological power. The coming years will reveal whether determined state-led development can overcome the immense technical and ecosystem challenges in this foundational industry.

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025