The field of programmable metamaterials has witnessed groundbreaking advancements in recent years, particularly in the realm of precision control. These engineered materials, designed to exhibit properties not found in nature, are now being fine-tuned with unprecedented accuracy, opening doors to applications ranging from adaptive optics to next-generation wireless communications.

At the heart of this revolution lies the ability to dynamically alter the electromagnetic, acoustic, or mechanical response of metamaterials through external stimuli. Researchers have developed sophisticated control mechanisms that allow for real-time adjustments at microscopic scales. This level of precision enables metamaterials to perform complex functions, such as steering electromagnetic waves with minimal energy loss or creating perfect absorbers for specific frequency ranges.

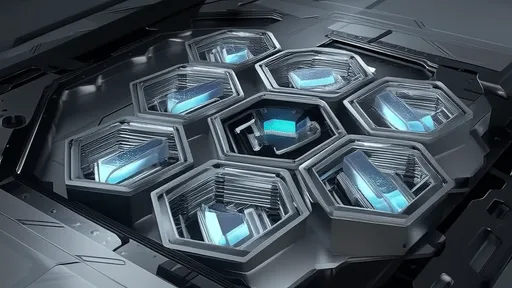

One of the most significant breakthroughs has been the integration of microelectromechanical systems (MEMS) with metamaterial structures. By embedding tiny actuators within the material's architecture, scientists can achieve sub-wavelength control over its properties. This approach has proven particularly effective in terahertz applications, where traditional tuning methods often fall short. The marriage of MEMS technology with metamaterial design represents a paradigm shift in how we approach material engineering.

The precision in controlling these materials doesn't stop at mechanical actuation. Recent developments in phase-change materials and liquid crystal integration have introduced new dimensions to programmable metamaterials. These components allow for gradual, smooth transitions in material properties rather than binary switching, enabling more nuanced control over wave propagation and energy manipulation. Such capabilities are proving invaluable in developing reconfigurable antennas and smart surfaces for 5G and beyond.

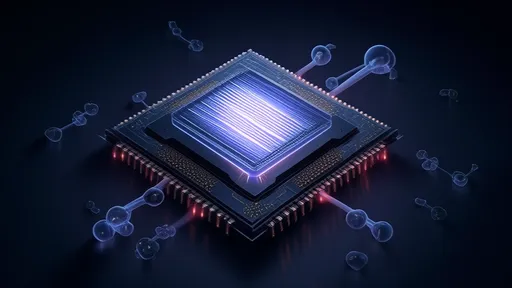

Machine learning algorithms are playing an increasingly important role in achieving this precision. By training neural networks on vast datasets of metamaterial behaviors, researchers can predict optimal configurations for desired outcomes. This data-driven approach complements traditional physics-based modeling, often revealing non-intuitive designs that outperform conventional structures. The synergy between artificial intelligence and metamaterial design is accelerating the pace of innovation in the field.

As control precision improves, so does the potential for practical applications. In the medical field, programmable metamaterials are being explored for advanced imaging systems and targeted therapies. The ability to precisely focus ultrasound waves, for instance, could revolutionize non-invasive surgery techniques. Similarly, in aerospace engineering, materials that can adapt their structural properties in flight could lead to more efficient aircraft designs with reduced mechanical complexity.

The challenge of maintaining precision at scale remains an active area of research. While laboratory demonstrations have shown remarkable control over small metamaterial samples, translating these successes to industrial-scale production presents hurdles. Manufacturing tolerances, material consistency, and control signal distribution all become more complex as the size of the metamaterial increases. Researchers are addressing these issues through novel fabrication techniques and distributed control architectures.

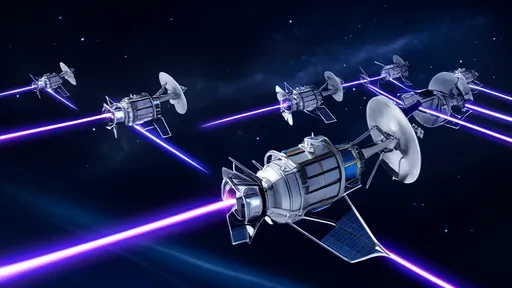

Looking ahead, the convergence of programmable metamaterials with quantum technologies promises to push the boundaries of precision even further. Quantum dots and superconducting circuits are being investigated as potential components for next-generation metamaterials that could operate at the quantum limit. Such developments might enable applications we can scarcely imagine today, from perfect quantum state transfer to ultra-secure communication systems.

The ethical implications of this technology are coming into focus as capabilities advance. The same precision that enables beneficial applications could potentially be used for surveillance or other controversial purposes. The scientific community is beginning to grapple with these questions, establishing guidelines for responsible development while preserving the open collaboration that drives innovation.

Industry adoption of programmable metamaterials is accelerating, with major technology firms investing heavily in research and development. As manufacturing processes mature and control systems become more robust, we're likely to see these materials transition from laboratory curiosities to essential components in commercial products. The coming decade may well be remembered as the period when programmable metamaterials entered the mainstream, transforming industries and enabling technologies that were previously confined to science fiction.

What makes this field particularly exciting is its interdisciplinary nature. Progress in programmable metamaterials draws from physics, materials science, electrical engineering, computer science, and numerous other disciplines. This cross-pollination of ideas fosters innovation and ensures that advances in precision control will continue to surprise and delight researchers and end-users alike.

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025