In a groundbreaking development for disaster response technology, researchers have unveiled a new generation of shape-shifting liquid metal robots capable of reconfiguring themselves to navigate complex environments. These remarkable machines represent a paradigm shift in search-and-rescue operations, offering unprecedented adaptability in the face of collapsed structures, flooded areas, and other hazardous scenarios where traditional rigid robots often fail.

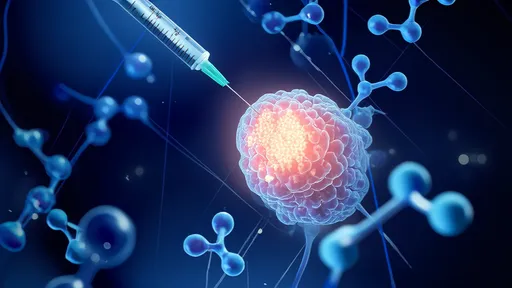

The core innovation lies in a novel gallium-based alloy that maintains liquid properties at room temperature while demonstrating extraordinary surface tension and electrical conductivity. When subjected to carefully controlled electromagnetic fields, the material can flow like mercury one moment and solidify into functional tools the next. This dual-phase capability allows a single robot to transform from a flowing liquid that seeps through cracks into a rigid gripper capable of lifting debris or a conductive probe for sensing survivors.

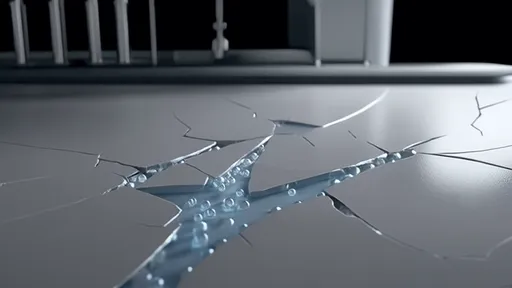

Recent field tests under simulated disaster conditions have demonstrated the technology's potential. During a mock earthquake scenario at the Swiss Federal Laboratories for Materials Testing and Research, a palm-sized unit successfully navigated through a maze of collapsed concrete beams by alternating between liquid and solid states. At one critical juncture, the robot flattened itself to a 2mm thickness to slip between structural elements before reforming into a three-fingered claw to turn off a simulated gas valve.

What sets these systems apart from conventional rescue robots is their ability to self-heal and redistribute mass. When damaged by falling debris or extreme temperatures, the liquid metal simply flows back together, maintaining functionality where mechanical robots would suffer catastrophic failure. This resilience proves particularly valuable in the unpredictable environments following natural disasters, where conditions can change rapidly and access routes may become blocked without warning.

The technology's potential extends beyond physical manipulation. Researchers at Tsinghua University have integrated biochemical sensors into the liquid matrix, enabling the robots to detect vital signs, chemical leaks, or radiation levels while in motion. As the units reconfigure, these sensors automatically reposition themselves to maintain optimal measurement capabilities - a feature impossible to achieve with fixed-sensor platforms.

Current prototypes demonstrate three primary operational modes: exploration (flowing through narrow spaces), manipulation (forming temporary tools), and bridging (creating conductive pathways for communication equipment). In a particularly striking demonstration, multiple units combined their mass to form a temporary antenna that restored emergency communications in a simulated urban disaster zone.

While the technology shows immense promise, significant challenges remain before widespread deployment. Researchers are working to improve control precision in turbulent environments and develop better methods for recovering the robots after mission completion. The team at MIT's Computer Science and Artificial Intelligence Laboratory recently made progress on this front, developing a magnetic nanoparticle tagging system that allows for easier retrieval of the liquid metal components.

Ethical considerations have also emerged regarding the potential environmental impact of liquid metal residues. The development teams assure that all current prototypes use biocompatible, non-toxic alloys that can be safely recovered or biodegraded if retrieval proves impossible. Ongoing research focuses on creating versions that utilize entirely organic liquid metals for even greater environmental safety.

Industry analysts predict that within five to seven years, we may see the first operational deployments of liquid metal rescue robots working alongside human teams in disaster zones. The technology's ability to access areas unreachable by either humans or conventional robots could revolutionize how we respond to earthquakes, mine collapses, and nuclear accidents. As climate change increases the frequency and severity of natural disasters, such adaptable systems may become essential tools for preserving human life in the face of catastrophe.

Looking ahead, researchers envision swarms of these robots working in concert - some flowing underground to stabilize foundations while others form temporary structures to shore up damaged buildings. The European Commission has already funded a multinational research initiative to explore how liquid metal systems might assist in underwater rescue operations and deep-sea infrastructure repair. What began as a materials science curiosity is rapidly evolving into one of the most promising frontiers in emergency response technology.

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025