In a groundbreaking advancement for materials science, researchers have developed a new class of self-healing ceramics capable of autonomously repairing cracks through embedded microcapsule technology. This innovation promises to revolutionize industries ranging from aerospace to biomedical engineering, where ceramic materials are prized for their durability but have historically suffered from brittleness and crack propagation.

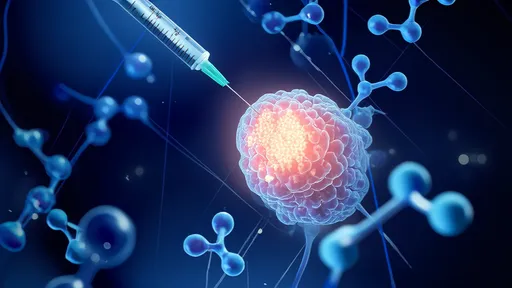

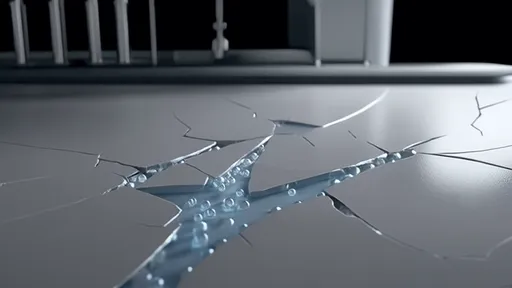

The core breakthrough lies in the integration of microscopic healing agents directly into the ceramic matrix. When cracks form, these microcapsules rupture, releasing liquid healing compounds that flow into the fissures and polymerize upon exposure to air or heat. Unlike previous self-healing materials that required external triggers, this system operates entirely through mechanical stimulus - the very act of cracking activates the repair mechanism.

Dr. Elena Vasquez, lead researcher at the International Materials Institute, explains: "What makes this technology extraordinary is its biomimetic design. We're essentially replicating how human skin heals minor cuts - damage triggers a built-in repair response without conscious intervention." Her team's latest publication in Advanced Materials demonstrates healing efficiency exceeding 85% for cracks up to 200 micrometers wide.

Industrial applications are already emerging. Turbine manufacturers report prototype ceramic blades surviving three times as many stress cycles before failure. In electronics, circuit boards with ceramic substrates show remarkable resistance to thermal cycling damage. Perhaps most impressively, dental implant trials reveal the microcapsule technology can potentially extend prosthetic lifespans by decades through continuous micro-fracture repair.

The environmental implications are equally significant. By dramatically extending product lifetimes, self-healing ceramics could reduce industrial waste streams. Early lifecycle assessments suggest ceramic components might achieve service lives measured in centuries rather than decades when the healing mechanism is properly maintained. This challenges traditional paradigms of planned obsolescence in consumer goods and industrial equipment alike.

Manufacturing challenges remain before widespread adoption. Current production methods struggle with uniform microcapsule distribution at commercial scales, sometimes creating weak points in the material structure. Additionally, the healing compounds have temperature limitations - most formulations lose effectiveness above 600°C. Research teams in Germany and Japan are reportedly developing high-temperature variants using metallic alloys instead of organic polymers.

Investment is pouring into the field, with venture capital funding for self-healing materials doubling annually since 2020. Major aerospace firms have established dedicated research partnerships with universities, while three startups focusing specifically on ceramic healing technologies have emerged from stealth mode this quarter alone. The global market for advanced ceramics, currently valued at $13 billion, is projected to incorporate self-healing variants across 40% of applications by 2035 according to Materials Tech Analytics.

Beyond industrial uses, architects are exploring visionary applications. Imagine skyscraper facades that seal hairline cracks before water infiltration occurs, or earthquake-resistant structural elements that autonomously repair between seismic events. The Venice Municipality recently commissioned a study on using self-healing ceramics for preserving historic buildings against rising sea levels and increasing flood frequency.

Ethical discussions are emerging alongside the technological progress. Some materials scientists caution against over-optimism, noting that while microcapsules address surface cracks, they cannot rebuild extensively damaged structures. There are also intellectual property battles brewing, with four competing patent families claiming fundamental aspects of the technology. The European Commission has initiated preliminary discussions about standardization and safety certification protocols.

Looking ahead, next-generation systems may incorporate multiple healing mechanisms. Early-stage research at Caltech combines microcapsules with vascular networks inspired by human circulatory systems, allowing continuous replenishment of healing agents. Another frontier involves "smart" capsules that release different compounds depending on crack depth or environmental conditions. Such advancements could make today's breakthroughs appear primitive within a decade.

For materials engineers, this represents a paradigm shift comparable to the introduction of carbon fiber or high-temperature superconductors. The ability to create ceramics that not only withstand extreme conditions but actively repair themselves opens design possibilities previously confined to science fiction. As production costs decrease - currently about 30% premium over conventional ceramics - adoption rates are expected to follow an exponential curve.

The coming years will likely see self-healing ceramics transition from laboratory marvel to industrial workhorse. With simultaneous advances in nanotechnology and machine learning-assisted materials design, we may be witnessing the dawn of a new era in materials science - one where the line between inert matter and living systems becomes increasingly blurred through engineered autonomy.

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025